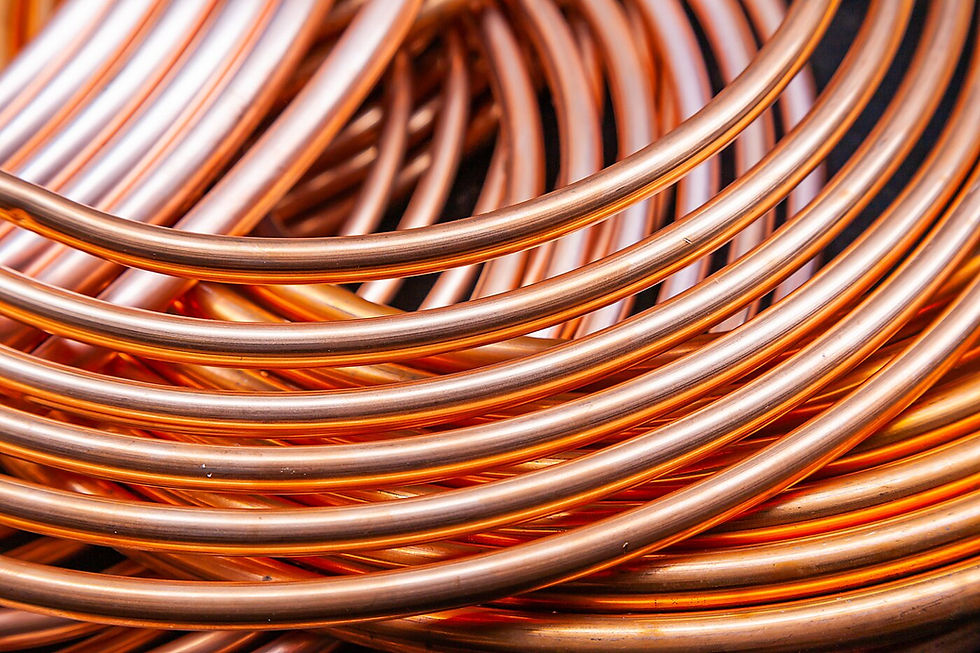

C106 R220 Copper Coil: Fewer Joints, Less Risk, Faster Installs

- P&P Non-Ferrous Ltd

- 5 days ago

- 3 min read

Copper is one of those materials that rarely gets value-engineered out for long. In plumbing, HVAC and building services it keeps coming back because it behaves predictably in fabrication, it resists corrosion in normal service environments and it carries heat and electricity efficiently.

What tends to change is not whether copper is used but how it is supplied. For many installers and fabricators, coil format in the right grade and temper is the difference between a clean run and a fitting-heavy workaround.

At P&P Bornmore Metals we stock copper coil in C106 R220 because it suits the reality of site work: long routes, limited access, tight programmes and a need to minimise leak paths.

What C106 actually gives you

C106 is the UK shorthand most engineers recognise for phosphorus-deoxidised copper often referenced as Cu-DHP. In practical terms, the deoxidised chemistry improves performance in joining and fabrication compared with coppers that retain more oxygen. That matters when your installation relies on consistent brazed or soldered joints and you want repeatable results without chasing intermittent porosity or inconsistent flow.

For plumbing and general pipework, C106 is widely accepted because it balances formability with in-service reliability. It is not a specialist electrical grade and that is an important point when specifications get copied across projects.

Why R220 and why coil

The temper is where copper coil earns its keep. R220 is the softer condition typically supplied in coils so the tube can be routed and formed without fighting springback. If you are trying to run continuous lengths through risers, ceiling voids or plantrooms, the ability to make gradual offsets and keep the line moving matters more than the nominal tensile values on a datasheet.

Coil format also changes the job mechanically. Fewer straight lengths means fewer cuts and fewer joints. In building services, every joint is a potential leak path and a potential delay during pressure testing. Reducing joint count is not just a quality improvement, it is a programme improvement. It also reduces the number of fittings you need to manage on site which helps when supply is tight or when projects are staged.

Where C106 coil fits best

In plumbing and domestic or commercial water services, C106 coil is often chosen for distribution runs where routing needs to be flexible and the installation needs to stay tidy. The grade is well understood by contractors and it is compatible with common joining approaches, whether you are soldering, brazing or using modern mechanical systems.

In HVAC, coil is particularly useful where lines need to be routed through congested spaces or where the layout is likely to evolve during installation. Being able to adjust on site without turning every change into a set of extra elbows keeps the job under control and helps maintain good flow characteristics.

For electrical applications, the key point is selection. Copper’s conductivity makes it attractive, but many electrical uses specify oxygen-free grades where conductivity consistency and purity are critical. If the application is primarily electrical and the specification is demanding, it is worth confirming whether an oxygen-free grade is required rather than defaulting to Cu-DHP. C106 is an excellent building services copper, but it should not be treated as a universal copper.

Stock that supports the pace of your project

C106 R220 copper coil remains a practical choice because it aligns with how work is actually done. It supports continuous runs, keeps joint count down and gives installers the flexibility to route reliably in real-world spaces. In most building services projects, that combination matters as much as the underlying material properties.

If you want help matching copper coil to your application, send us the size details, wall thickness and typical run lengths. We will confirm the most suitable stock option and make sure the specification matches the joining method and the service conditions.

Comments